How to install cold process roofing: Flawless 2025

Why Cold Process Roofing Is Revolutionizing Modern Roof Installation

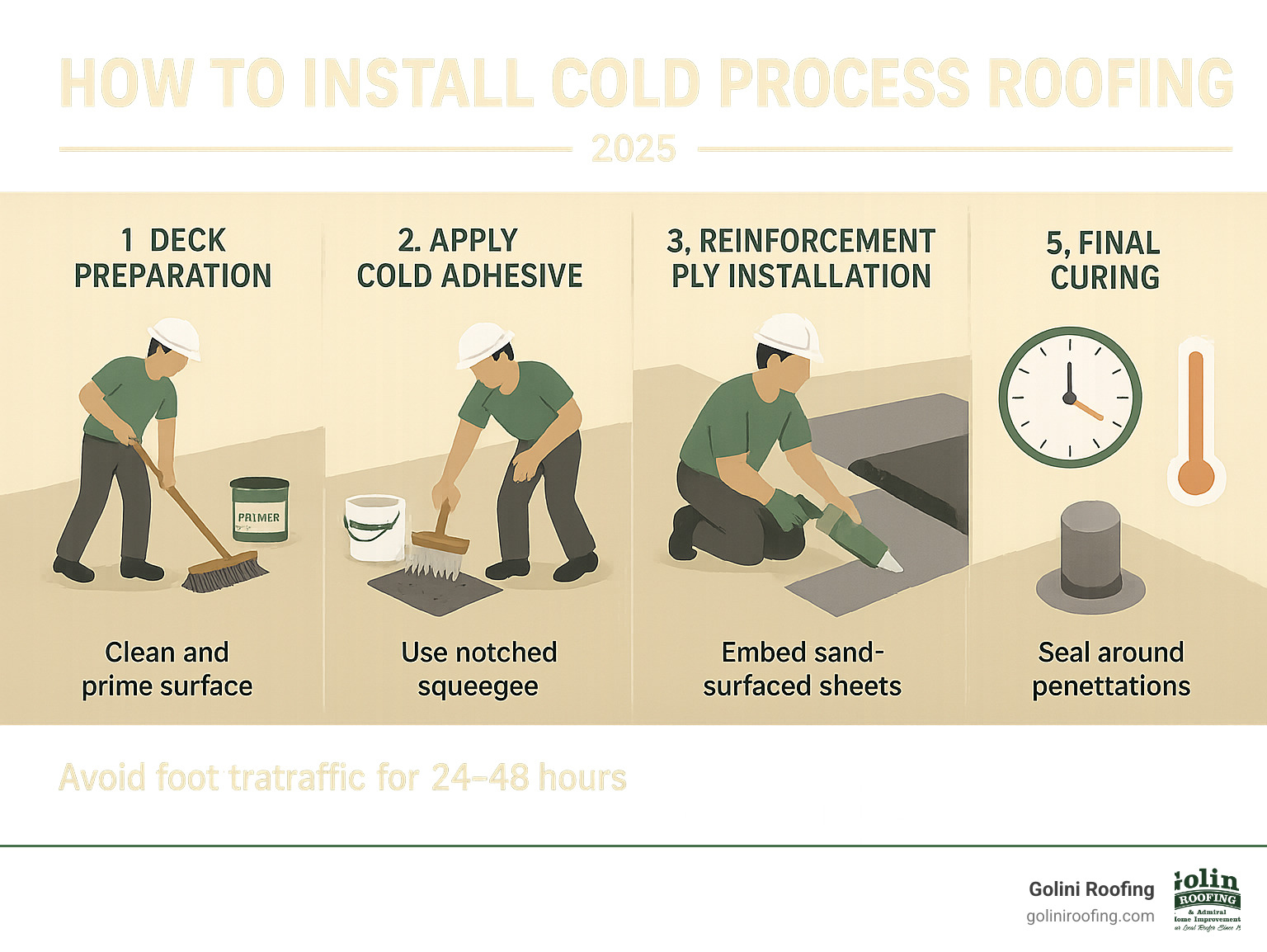

How to install cold process roofing involves applying multiple plies of reinforcement sheets using cold adhesives instead of hot asphalt, creating a durable, waterproof membrane. The essential process includes:

- Prepare the roof deck – Clean, inspect, and prime the surface.

- Apply cold adhesive – Use a notched squeegee at 1.5-2.0 gallons per 100 sq ft.

- Install reinforcement plies – Embed sand-surfaced sheets in wet adhesive.

- Overlap correctly – Maintain proper lap dimensions and seal seams.

- Allow proper curing – Avoid foot traffic for 24-48 hours minimum.

- Install flashings and details – Seal all penetrations and edges.

Cold process roofing systems consist of multiple reinforcement plies set in a cold, solvent-based or water-based adhesive. These systems offer significant advantages over traditional hot-applied methods, including improved safety with no open flames or hot kettles, reduced equipment needs, and the ability to work with smaller crews.

The process eliminates dangerous hot asphalt kettles while providing durability comparable to traditional built-up roofing. Most applications can be completed by just three or four workers, making it an efficient choice for new construction and roof restoration.

Cold adhesives are composed of bitumen, solvent, fibers, fillers, and stabilizers, sometimes with rubber polymers like SBS for improved performance. The adhesive creates a strong bond as the solvent evaporates.

With decades of experience in the roofing industry, it’s clear that mastering how to install cold process roofing provides exceptional results. Proper installation delivers outstanding performance when executed with precision.

Understanding Cold Process Roofing Systems

Cold process roofing is a safer, modern alternative to traditional hot-applied methods. Instead of dangerous hot asphalt kettles reaching over 400°F, how to install cold process roofing relies on specially formulated adhesives that work at ambient temperatures, making the process safer and easier.

The key is the cold adhesive—a sophisticated mix of bitumen, solvents, fibers, fillers, and stabilizers. Many include rubber polymers like SBS (Styrene-Butadiene-Styrene) for flexibility and durability. As solvents evaporate, a “solvent weld” forms, bonding the membrane plies at a molecular level.

Reinforcement plies of fiberglass or polyester form the roof’s backbone, providing strength and stability. It’s critical to use sand-surfaced sheets, as the sandy texture is essential for the adhesive to grip. Film-backed sheets are incompatible with these systems.

Most cold process systems use a multi-ply configuration, embedding multiple layers of reinforcement in successive coats of adhesive. This creates redundancy, ensuring that if one layer is compromised, others provide backup protection.

Protective coatings complete the system. These can be elastomeric coatings that stretch with the building or aluminum coatings that reflect heat and protect against UV damage. Some systems use specialized coatings for areas with ponding water.

The versatility of cold process systems makes them suitable for new construction, repairs, or restoration over existing smooth roofs. With proper installation, manufacturers typically offer warranties from 15 to 25 years, a testament to their reliability.

What Are the Main Advantages?

Contractors and building owners prefer cold process roofing for several clear reasons:

Improved safety is the top benefit. No open flames or hot kettles eliminates fire hazards and severe burn risks, making it ideal for sensitive locations like schools and hospitals.

Equipment simplicity streamlines job site logistics. Without kettles or torches, crews can focus on roofing. The smaller equipment footprint allows easier access to tight job sites.

Low odor and VOC options minimize disruption for building occupants. Many modern adhesives meet strict environmental standards, allowing normal operations to continue.

Monolithic membrane performance delivers superior waterproofing. The “wet-on-wet” technique—where base coat, reinforcement, and top coat are applied while wet—creates a seamless, fully bonded membrane.

Durability and flexibility are key. SBS-modified adhesives create an elastomeric film that moves with the building, preventing the cracking that can plague rigid systems.

Cost-effectiveness is achieved through smaller crews, simpler equipment, and potentially lower insurance rates due to reduced fire risk, which can offset material costs.

Common System Components and Materials

Cold-applied adhesives come in two main types. Solvent-based adhesives create strong bonds but require excellent ventilation due to flammability. They are often self-priming, though absorptive substrates may need more. Water-based adhesives are environmentally friendly with lower VOCs and no flammability issues, but they are vulnerable to freezing.

SBS-modified bitumen membranes are flexible, durable, and pair perfectly with cold adhesives, making them a top choice for low-slope roofs.

The reinforcement sheets must be sand-surfaced for proper adhesive bonding.

Base sheets and cap sheets form the foundation and top layer of the multi-ply system, each playing a role in waterproofing and protection.

Protective coatings add the final layer of defense. Elastomeric coatings provide flexibility and reflective surfaces, while aluminum coatings excel at reflecting heat and protecting against UV degradation.

Pre-Installation: Preparing for a Successful Project

Proper preparation is the key to a successful cold process roofing installation. Every step, from cleaning the surface to ensuring materials are at the right temperature, is crucial when learning how to install cold process roofing.

Meticulous preparation is the foundation of a long-lasting roof. What happens before the first drop of adhesive touches the deck often determines whether a roof lasts 15 or 30 years.

The prep phase begins with a thorough site assessment. We check the existing roof or deck for structural integrity, using infrared scans if needed to detect hidden moisture. Any damaged boards are replaced.

Next, we perform deck repairs, filling all cracks and holes. The surface must be smooth and free from depressions where water could pool, as ponding water compromises roof longevity.

Cleaning the surface is non-negotiable. The deck must be spotless—free of debris, dust, oil, and grease—to ensure proper adhesion. We typically use a soft broom or blower.

Removing moisture is equally critical, as the surface must be completely dry. Moisture is the enemy of adhesion and can cause adhesive failure.

For absorptive surfaces like masonry, priming the deck is essential. An appropriate asphalt primer is used to create a receptive surface for the adhesive. Primers must dry thoroughly before proceeding.

Material storage and handling require special attention in Massachusetts, where temperatures vary. Adhesives and roll goods must be stored in a clean, dry, indoor environment, protected from freezing and direct sunlight. We aim for storage temperatures of at least 50°F, with 70°F or higher being ideal.

When temperatures are below 50°F, materials must be stored in a heated area for at least 24 hours pre-installation to ensure proper adhesive viscosity and material flexibility.

Essential Tools and Materials for Cold Process Roofing Installation

The right tools are essential for a smooth installation. Here’s what we have ready:

- Safety equipment: Safety glasses, impervious clothing, sturdy work boots, and chemical-resistant safety gloves. For solvent-based products, proper ventilation and masks are necessary.

- Notched squeegees: A 5/16-inch V-notched squeegee is crucial for applying adhesive at the correct rate of 1.5-2.0 gallons per 100 square feet.

- Rollers: A heavy roller helps embed reinforcement plies and remove air pockets.

- Brushes: For detail work and smaller areas.

- Spray equipment: For larger projects, requiring specific pressure and tip sizes.

- Utility knives, measuring tape, and chalk line: For precise cutting and layout.

Preparing the Roof Deck and Storing Materials

The roof deck must be sound, clean, and completely dry. We inspect the existing roof, remove all debris and contaminants, and ensure any moisture is dried out. For new construction, the deck must meet the same standards.

Absorptive surfaces like concrete require a primer, which must dry completely before adhesive application. We never rush this step.

Given New England’s weather, proper material storage is vital. Adhesives and rolls must be kept in a dry, indoor environment between 60°F and 80°F, protected from freezing and sun. If ambient temperatures are below 50°F, materials must be conditioned in a heated space for at least 24 hours to ensure optimal viscosity and flexibility.

We also unroll and cut wrinkled material into shorter lengths, allowing them to relax before application. This simple step prevents issues like “fishmouthing” and ensures a professional installation.

The Step-by-Step Guide to How to Install Cold Process Roofing

With preparation complete, the installation begins. This stage demands precision. Following the correct steps when learning how to install cold process roofing is essential for creating a durable, watertight membrane that relies on ambient temperature curing rather than dangerous hot kettles.

Proper Techniques for Applying Cold Process Adhesives

Correct adhesive application is the foundation of a successful installation. First, we measure the application area and calculate the required adhesive based on manufacturer specifications, typically 1.5 to 2.0 gallons per 100 square feet for interply layers. For example, a 1,000 sq ft area at 1.5 gal/100 sq ft requires 15 gallons. We calculate adhesive needs for smaller, manageable sections to ensure uniform coverage.

Our primary method is the squeegee technique. Using a 5/16-inch V-notched squeegee, we spread the adhesive evenly. It’s critical to apply adhesive no more than 5 feet ahead of the reinforcement to prevent it from skinning over before the material is embedded.

For larger projects, roller and spray techniques can increase efficiency. Spray application requires specific equipment and material temperatures (often heated to at least 95°F).

Avoiding over-application is crucial. Too much adhesive causes the membrane to “float,” slows curing, and results in poor adhesion. Conversely, under-application creates weak bonds that fail over time. We continuously monitor application rates to hit the sweet spot.

Some systems use a “wet-on-wet” application, where the base coat, fabric, and top coat are all applied while wet. This creates a strong monolithic bond with excellent interlaminary strength.

How to Install Reinforcement Plies and Flashings

Once the adhesive is down, we quickly embed the reinforcement plies to unify the system.

We embed reinforcement sheets by carefully laying the fiberglass or polyester sheets into the wet adhesive. Using a broom or roller, we press the membrane into the adhesive from the center outward, eliminating air pockets and wrinkles. The goal is complete embedment for a solid, fully adhered system.

Proper overlapping requires strict adherence to manufacturer specifications—typically 25 inches for full widths in a shingle fashion, with 3-inch side laps and 6-inch end laps. These overlaps are required for a watertight membrane. We also ensure sufficient coating between overlaps to maintain a monolithic seal.

Installing flashings correctly is critical, as this is where most leaks originate. Every penetration, edge, and vertical surface needs specialized attention.

- Drains: We taper insulation to create sumps and embed plies directly into the drain bowl, often using lead sheets and multiple courses of mastic for a secure seal.

- Vents and Pipes: We use silicone pipe boots and ensure 4-8 inches of waterproofing around each penetration, sealed with mastic and reinforcement fabric.

- Parapet walls and equipment curbs: Base flashings must extend the plies to cant strip edges or tops for continuous protection up vertical surfaces.

- Irregularly shaped penetrations: We use pitch pockets filled with non-shrink grout and sealed with specified water-shedding materials.

A roof is only as good as its flashings, which are common points of failure if not installed correctly.

Technical guidance on cold-applied mastics.

Critical Factors for a Flawless Installation

Experience shows that successful cold process roofing depends heavily on managing environmental factors. Weather conditions directly impact adhesive performance and curing, making them critical to a long-lasting installation when learning how to install cold process roofing.

Temperature is the most critical factor. Cold adhesives thicken in chilly weather, making them hard to spread, and they cure more slowly. Hot weather can cause solvents to evaporate too quickly, compromising the bond.

While safer than hot asphalt, cold process requires new safety protocols, including proper ventilation for solvent-based adhesives and avoiding all ignition sources. The slower curing process also means the roof surface cannot handle foot traffic for longer periods.

Cold Weather Application and Safety Precautions

With the right precautions, these systems can be installed successfully in cooler weather. Most cold adhesives require ambient temperatures between 35°F and 100°F, but the material temperature is also important. Many products need to be at least 60°F for squeegee application, while spray applications may require material heated to 95°F or higher.

When temperatures drop below 50°F, we store all materials in heated areas for at least 24 hours before use. This step is essential. Cold materials are stiff and difficult to work with, and adhesives become too thick to spread properly.

The increased viscosity of cold adhesives at low temperatures can lead to uneven application. We allow extra time for materials to warm up.

Slower curing times are expected in cold weather. Curing can take days in cold weather versus hours in warm weather, requiring extra planning and protection. We avoid foot traffic on uncured areas for longer periods, sometimes 48 hours or more, as cold adhesives have lower initial “green strength” and are more susceptible to displacement.

Personal protective equipment is always essential. Crews must wear impervious clothing, rubber gloves, and safety glasses. For solvent-based products, we ensure proper ventilation to allow solvents to flash off safely and prevent vapors from entering buildings. We also maintain strict protocols for avoiding ignition sources like smoking or sparks, as these materials are combustible.

ARMA recommendations for cold weather roofing.

Ensuring Quality Control and Proper Curing

Quality control for cold process roofing is unique due to its slower curing time. Continuously monitoring temperature and adhesive application rates is critical. Incorrect amounts lead to either a slow-curing, unstable membrane or weak bonds that won’t withstand weather extremes.

We inspect seams carefully for proper adhesion, especially with modified bitumen sheets. Visual inspection and gentle pressure testing help identify areas needing more attention.

Preventing membrane displacement requires vigilance during the extended curing period. We implement strict housekeeping, keeping equipment off newly installed areas and minimizing foot traffic until a proper cure is achieved.

Understanding “green strength”—the initial bond strength—is crucial. The membrane needs time to develop its full adhesive strength. Rushing this process by allowing premature traffic can cause displacement, wrinkles, or compromised adhesion.

Allowing adequate curing time is non-negotiable. Some systems require 30-day curing periods before protective coatings can be applied. We mark new sections and restrict access until the manufacturer’s recommended time has passed. Clear communication and strict access control are necessary to prevent foot traffic from compromising an uncured membrane.

Conclusion

Learning how to install cold process roofing is about mastering a craft that combines modern technology with proven roofing principles. We’ve covered every aspect, from deck preparation and adhesive application to embedding reinforcement plies and installing critical flashings.

The beauty of cold process roofing is its approach. By eliminating the dangers of hot asphalt and open flames, these systems improve safety, reduce environmental impact, and offer superior long-term durability, making them a smart investment. When installed correctly, they create a monolithic, flexible membrane that withstands New England’s harsh weather.

However, this guide provides an overview; complex roofing projects require professional expertise to guarantee a durable, leak-free result. The nuances of managing temperature effects, executing intricate flashing details, and ensuring proper curing demand the skill of seasoned professionals. The difference between a good roof and a great one lies in these details, learned through years of hands-on experience.

For homeowners and businesses in Massachusetts—from Burlington to Woburn—trusting an experienced contractor is essential. A reputable contractor brings meticulous attention to detail to every cold process installation, ensuring your property gets the lasting protection it deserves.

Don’t leave your roof to chance. Contact a professional for a roofing consultation and learn how their expertise can provide peace of mind for years to come.