Installation process for built up roofing: Flawless 101

Why Built-Up Roofing Remains a Top Choice for Commercial Properties

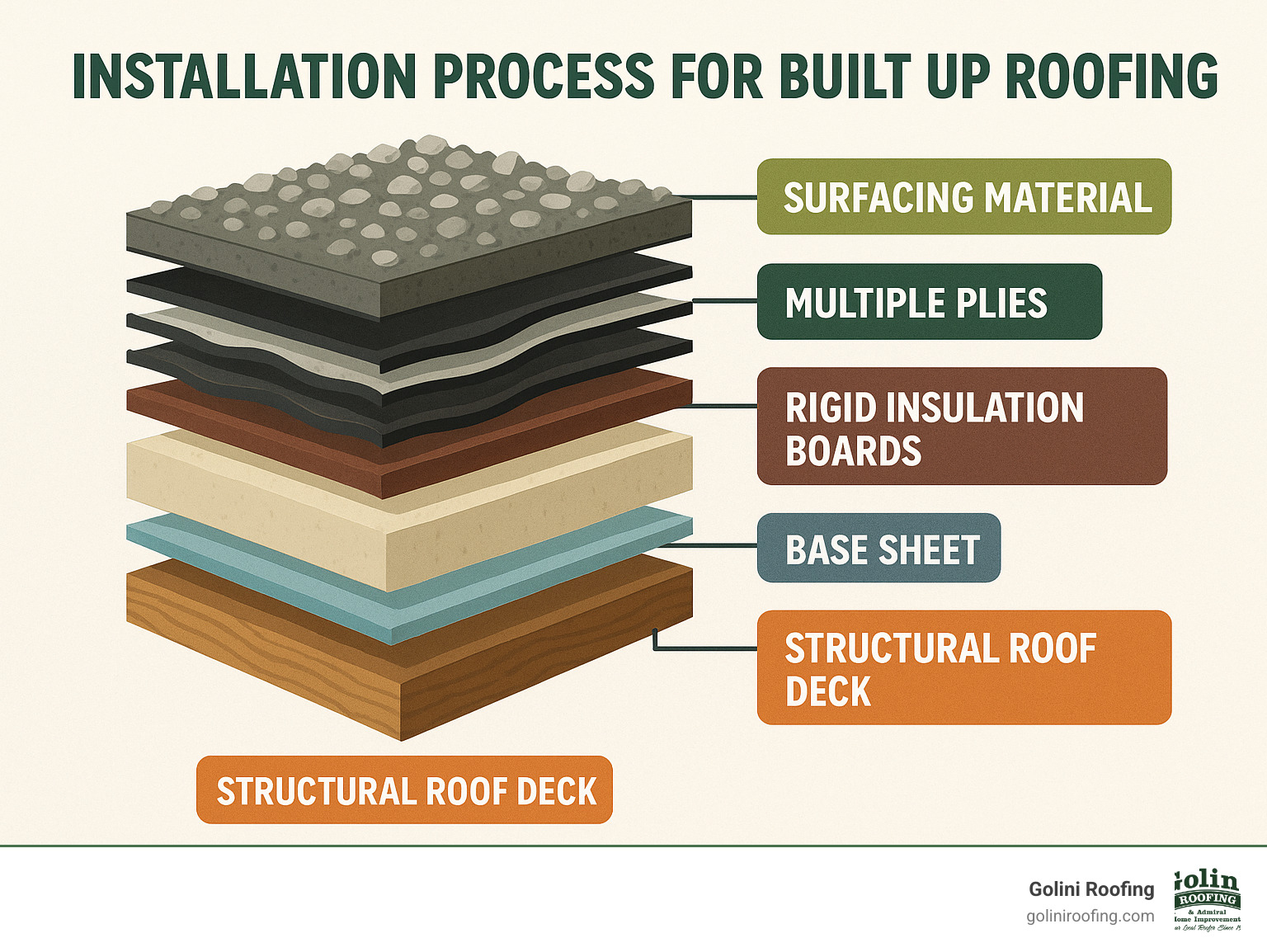

The installation process for built up roofing involves applying multiple layers of bitumen and reinforcing fabrics to create a durable, waterproof membrane system. Here’s the essential process:

- Prepare the roof deck – Clean, dry, and inspect for structural integrity

- Install vapor retarder – Prevent moisture accumulation between layers

- Apply insulation – Add thermal performance and create a stable base

- Install base layer – Secure the foundation sheet with fasteners or adhesive

- Build up plies – Alternate 3-5 layers of hot bitumen and reinforcing fabric

- Add surfacing material – Apply gravel, mineral granules, or protective coating

- Final inspection – Check seams, flashings, and ensure watertight seal

Built-up roofing (BUR) systems have protected commercial buildings for over a century. Often called “tar and gravel” roofs, these multi-layered systems create what the industry calls redundant protection – if one layer fails, others continue working.

The process requires skilled contractors who understand both hot asphalt application (reaching 425°F+) and cold-applied methods. Industry data shows BUR installation costs average $2.50 to $18 per square foot, though project costs vary based on building specifications and local conditions.

Modern BUR systems offer excellent durability, lasting 20-40 years with proper maintenance. They provide superior fire resistance, UV protection, and can handle ponding water better than many single-ply alternatives.

Decades of experience installing commercial roofing systems have shown that BUR systems, while labor-intensive, deliver the best longevity when installed correctly.

Pre-Installation Essentials: Preparing for Success

Preparing for a built-up roofing system is critical. The installation process for built up roofing depends on thorough prep, and after years in this business, experienced professionals know rushing this stage leads to problems.

Roof deck preparation is the foundation for the entire system; everything else depends on getting this right. We start by completely cleaning and drying the surface, removing all debris, old roofing materials, and dirt. Proper adhesion between layers simply cannot happen on dirty or wet surfaces.

The structural integrity check comes next, and it’s crucial because built-up roofs carry serious weight. We’re talking about 5-7 pounds per square foot – significantly heavier than lightweight single-ply systems. Your building’s frame and deck need to handle this load, so we repair any damage and ensure everything is rock-solid before moving forward.

Safety considerations are especially important when dealing with hot asphalt that reaches over 425°F. Those high temperatures create fumes and odors that require proper ventilation and personal protective equipment. We take fire prevention seriously, keeping extinguishers handy and having trained supervisors monitor the site for hours after hot work finishes.

Weather plays a huge role in timing your installation. We need ideal conditions – dry weather with temperatures of 45°F and rising. Rain, snow, and wet surfaces are absolute no-gos because trapped moisture will destroy your roof’s performance. For certain materials like mineral cap sheets, we won’t start if temperatures drop below 50°F.

For more details about commercial roof inspections, reach out to an experienced roofing team.

The Importance of a Clean and Sound Roof Deck

Here’s the truth: every successful installation process for built up roofing starts with a pristine, structurally sound deck. We’ve seen too many problems that could have been avoided with proper preparation at this stage.

Ensuring proper adhesion means getting every bit of debris, moisture, and contamination off that surface. When we clean a deck, we’re not just sweeping up; we’re creating the perfect foundation for multiple layers of roofing materials to bond together.

Checking for structural soundness takes on extra importance with built-up systems because of their weight. The heavy nature of BUR systems means your building’s frame must be in excellent condition. We carefully inspect every square foot, looking for weak spots, damage, or areas that need reinforcement.

Making repairs now, before we start layering materials, saves you money and headaches down the road. Fixing underlying deck problems after installation is much more complicated and expensive. For more information about flat roof repair, contact an experienced roofing team.

Weather and Safety Protocols

Weather is a critical factor in BUR installation. We’ve learned to work with it, not against it.

The ideal temperature range for BUR installation is 45°F and rising, with dry conditions. We avoid unsuitable weather like rain, snow, or high humidity because trapped moisture will cause problems for years. Mineral cap sheets, for instance, cannot be applied when temperatures drop below 50°F.

Hot-mopped asphalt safety requires serious attention to detail. We’re heating bitumen to extreme temperatures, which creates fumes that need proper ventilation to protect our crew and your building occupants. Our teams wear appropriate protective equipment and follow strict protocols around fire prevention.

Cold-applied safety benefits have made this process much more worker-friendly. These modern systems eliminate toxic fumes while providing the same durability as traditional hot-applied methods.

Proper ventilation and fire prevention measures remain non-negotiable regardless of which method we use. We keep fire extinguishers within reach, ensure adequate airflow, and maintain trained supervision on-site for several hours after completing hot work to watch for any signs of smoldering.

The Step-by-Step Installation Process for Built-Up Roofing

With the roof deck prepared, we begin the installation process for built up roofing. This is where craftsmanship shines as we build multiple layers to create a fortress against the elements.

Building a BUR system is like making lasagna; each layer has a purpose, and together they create something incredibly strong. The magic happens through the careful combination of bitumen (your waterproofing hero, usually hot asphalt), reinforcing fabrics (the muscle of the system, typically fiberglass or organic felts), and surfacing materials (the protective shield on top, like gravel or reflective coatings).

What makes BUR systems so reliable is this layered approach. If one layer gets damaged, the others keep doing their job – that’s what we call redundant protection, and it’s why these roofs can last 30 years or more with proper care.

For more information about the roof installation process, consult with a professional roofing contractor.

Step 1: Installing Insulation and a Vapor Retarder

Before we start building up waterproof layers, we need to create the right foundation with insulation and moisture control. The insulation boards – whether polyisocyanurate, mineral fiber, or gypsum – get laid out carefully across the prepared deck. We always stagger the joints by at least 6 inches when using multiple layers, which prevents thermal bridging and gives you consistent energy performance.

Good insulation provides thermal performance that helps the entire BUR system work better. In winter, it keeps heat inside your building. In summer, it helps your cooling system work more efficiently.

The vapor retarder is an invisible shield that prevents moisture from your building’s interior from sneaking up into the roofing system. Trapped moisture is a roof’s worst enemy, causing blisters, reducing its lifespan, and creating expensive headaches. Moisture control through proper vapor retarder placement is absolutely critical for long-term success.

Step 2: Applying the Base Layer

With our foundation layers in place, we move to installing the base sheet – the anchor for everything that follows. This robust roofing felt is designed to create rock-solid adhesion to the substrate while providing immediate strength to the roof assembly.

The fastening methods we use depend on your specific roof deck. On wood or other nailable surfaces, we use specialized roofing fasteners spaced according to manufacturer specifications. For concrete decks, we rely on hot asphalt or cold-applied adhesives to create that crucial bond.

Creating a foundation means getting the overlaps just right – typically 4 inches at the ends and 2 inches on the sides. These engineered overlaps are required to prevent water intrusion. The base sheet becomes the launching pad for all the waterproof layers that follow.

Step 3: The Built-Up Roofing Installation Process of Adding Plies

Here’s where the artistry of the installation process for built up roofing comes alive. This step is all about building the alternating layers that give BUR systems their legendary durability.

We start by applying a uniform layer of hot asphalt (bitumen) heated to the perfect temperature – usually around 425°F. This requires professional skill; the asphalt must be at the correct temperature to bond without damaging materials or creating hazards.

Then comes the mop-and-flop method – we immediately unroll the reinforcing fabric (felt) directly into that hot asphalt while it’s still at optimal temperature. The timing here is everything. We never apply hot asphalt more than 6 feet ahead of where we’re laying the felt, and in cooler weather, we keep it to just 5 feet. This ensures the asphalt stays hot enough to fully embed the felt and create a perfect bond.

We repeat this dance of hot asphalt and felt, building up typically 3-5 plies depending on your roof’s requirements. Each layer adds another level of waterproofing and strength. Ensuring full adhesion means watching for air bubbles and making sure each layer bonds seamlessly with the one below it.

This process requires skill and patience. Rushing it leads to problems, but doing it right ensures a roof that protects your investment for decades. For more technical details, you can learn about BUR composition.

Finishing the System: Surfacing and Application Variations

Once the multi-layered membrane is complete, we apply the surfacing material. There are different ways to install BUR systems, and understanding them helps you choose the best option for your property.

| Feature | Hot-Applied Installation | Cold-Applied Installation |

|---|---|---|

| Bitumen State | Heated to high temperatures (425°F+) in kettles | Applied at ambient temperatures, often from drums |

| Bonding Agent | Hot asphalt (bitumen) | Cold-process adhesives (modified asphalt emulsions) |

| Fumes/Odor | Significant fumes and odors due to heating | Minimal to no toxic fumes, safer for occupants and crew |

| Application | Mopped or poured | Squeegeed, rolled, or sprayed |

| Speed | Can be faster for large areas due to rapid setting | Generally slower due to adhesive curing times |

| Equipment | Kettles, mops, tankers, specialized safety gear | Pumps, sprayers, rollers, squeegees |

| Historical Use | Traditional, time-tested method | More common modern method, gaining popularity |

| Safety | Higher safety risks (burns, fumes, fire) | Lower safety risks, no open flame or extreme heat |

The traditional hot-applied method has protected buildings for over a century and is still incredibly effective. However, cold-applied systems have been gaining ground because they offer the same durability with significantly improved safety for crews and building occupants.

There’s also the ballasted system approach, where heavy stones or pavers hold the layers in place through sheer weight rather than adhesion. While less common for traditional BUR, it’s another variation worth knowing about.

Choosing the Right Surfacing Material

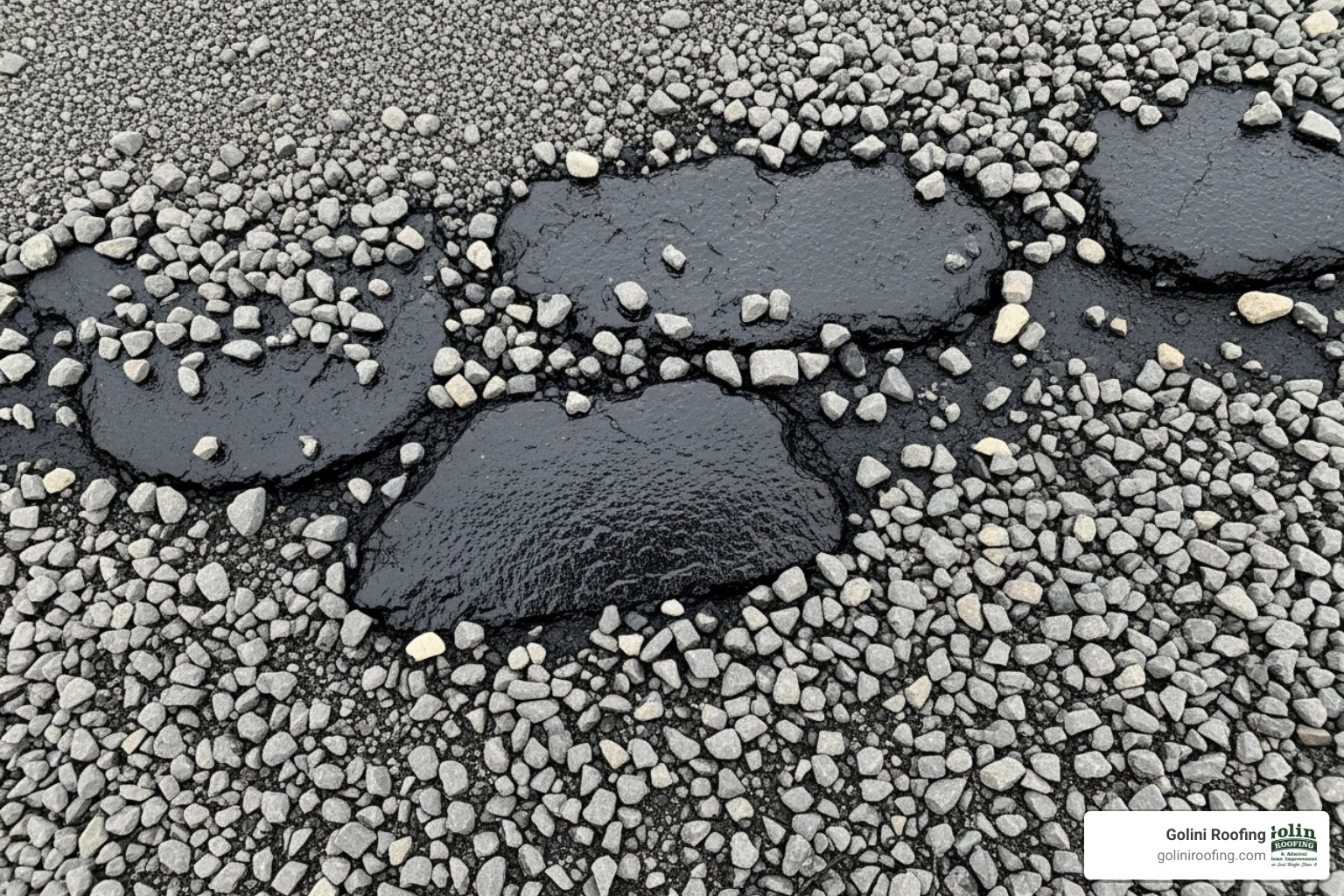

The surfacing material is your roof’s sunscreen, raincoat, and armor. It’s the final protective layer in the installation process for built up roofing, and choosing the right one is critical for your roof’s long-term performance.

The surfacing material has three main jobs. First, UV protection is crucial because ultraviolet rays break down bitumen over time. Second, weather resistance means standing up to everything from hail storms to foot traffic. Third, fire resistance is where many surfacing materials shine, particularly gravel, which significantly boosts the roof’s fire resistance.

Gravel or slag surfacing gives you that classic “tar and gravel” look. We broadcast clean roofing gravel over a flood coat of hot bitumen at about 400 pounds per square, or slag at 300 pounds per square. It’s extremely tough, providing excellent UV and fire resistance.

Mineral granules work similarly to what you’d find on asphalt shingles, embedded into the top layer. They offer great UV protection and come in various colors.

Reflective coatings are the modern energy-saver option. These paint-like substances – usually acrylic or silicone – get rolled or sprayed onto the surface. They’re fantastic for reflecting sunlight and reducing heat absorption, which can lower your cooling costs.

The right choice depends on your specific needs, local climate, and energy efficiency goals. We help you weigh these factors to pick the perfect surfacing for your building.

Understanding the Cold-Applied Installation Process for Built-Up Roofing

While hot asphalt has been the go-to method for decades, cold-applied installation is becoming the preferred choice for many commercial clients. It’s a modern approach that delivers the same excellent results with significant advantages.

Instead of heating bitumen to 425°F+, cold-applied systems use specially formulated adhesives that work at normal temperatures. This simple change makes a world of difference on the job site.

No toxic fumes is probably the biggest game-changer. With cold-applied methods, strong odors are eliminated. Your building occupants can go about their business without disruption, and our crews work in a much healthier environment.

Safer application means no open flames, no risk of burns from hot materials, and no fire hazards. This creates a smoother, less stressful work environment.

We apply these cold-process adhesives using squeegees or spray equipment. The curing time can be longer – sometimes up to 28 days before certain surface coatings can be applied – but the safety benefits and ease of application make it worthwhile.

Cold-applied BUR systems perform as well as traditional hot-mop installations, offering the same strength and durability with a safer, more occupant-friendly process.

Post-Installation: Final Checks, Timelines, and Lifespan

After applying the final surfacing material, our work isn’t quite done. The post-installation phase of the installation process for built up roofing is critical to ensuring your new roof performs as it should for decades.

We conduct a thorough final inspection. Our experienced team carefully examines every square inch of the completed system, looking for any potential weak spots. We pay special attention to all seams where materials overlap, checking that they’re properly sealed and adhered.

The flashing and penetrations around vents, pipes, and HVAC equipment get extra scrutiny. These areas are where most roof leaks start, so we make certain they’re watertight. We also inspect the perimeter edges and any transitions. This quality control check prevents small oversights from becoming major headaches.

Any minor issues we find are addressed immediately. It’s much easier to fix a small problem now than to deal with water damage later. Once everything passes our rigorous standards, we clean up the job site completely.

The installation process for built up roofing is labor-intensive. It requires skilled craftsmen who understand layered construction, careful coordination, and strict adherence to proven procedures. Because we’re building up multiple layers systematically, it takes time. You can’t rush a quality BUR installation.

This labor-intensive nature is exactly what contributes to the system’s exceptional durability. Every layer is carefully applied and inspected. This meticulous attention to detail during installation directly translates to superior long-term performance.

When it comes to typical timelines, the duration depends on roof size, weather, and system complexity. A straightforward commercial BUR installation might take several days, while larger projects can extend to weeks. Weather plays a significant role, as we can’t work in rain or extreme cold.

The payoff for this careful, methodical approach is an impressive expected lifespan. With proper installation and regular maintenance, built-up roof systems typically last 20 to 30 years. With meticulous care and proactive maintenance, we’ve seen BUR systems perform for 40 years or more. That kind of longevity makes them an excellent investment.

This durability comes from redundant protection. If one layer develops an issue, the other layers continue protecting your building. It’s like having multiple insurance policies working together to keep you dry.

For more information about commercial roof maintenance plans, it’s best to consult with a roofing professional. Regular maintenance is the key to maximizing your BUR system’s lifespan.

Frequently Asked Questions about Built-Up Roofing

After decades of installing built-up roofs, roofing professionals have heard just about every question imaginable. Here are answers to the most common ones.

How long does a built-up roof last?

A properly installed BUR system typically delivers 20-30 years of reliable performance. With regular maintenance and timely repairs, they can last well beyond 40 years.

The secret lies in multi-layered construction. When one layer shows wear, the others keep working. Regular inspections catch small issues before they become big headaches, which is why we always recommend staying on top of maintenance.

For more information about roof lifespans, consult a qualified roofing contractor.

How heavy is a built-up roofing system?

Built-up roofs are heavy. A typical BUR system weighs 5-7 pounds per square foot, making them considerably heavier than single-ply membrane systems.

This substantial weight is why we conduct a thorough structural assessment during the installation process for built up roofing. The building’s structure must support this load safely for decades.

Can a built-up roof be installed in any weather?

No, the weather must be right. Built-up roofing installation requires specific weather conditions to ensure a successful, long-lasting system.

We need dry conditions with moderate temperatures – ideally 45°F and rising. Rain, snow, or wet surfaces are absolute no-gos. Trapped moisture between layers creates blisters and can lead to premature system failure.

Temperature matters too. Mineral surfaced cap sheets shouldn’t be applied below 50°F because they need warmth for good adhesion. Patience with the weather pays off with a roof that performs beautifully for decades.

The weather requirements are all part of setting your roof up for success from day one.

Conclusion: Ensure a Flawless Installation for Your Commercial Property

The installation process for built up roofing is a craft that blends old-world expertise with modern precision. From preparing a spotless roof deck to the final protective surfacing, every phase demands attention to detail that only comes from years of hands-on experience.

What makes built-up roofs a standout choice for commercial properties? It’s the combination of exceptional durability, superior waterproofing, and impressive longevity. This multi-layered construction creates redundant protection, where multiple barriers work together to keep your building dry and secure.

BUR installation is not a DIY job or one for inexperienced contractors. This is a meticulous process that requires skilled professionals who understand the science behind each layer and the importance of getting every detail right. One shortcut or oversight can turn a 30-year roof into a 5-year headache.

Professional roofing companies have been perfecting this craft for decades. They ensure proper structural support, manage safety protocols, and time the work around local weather, handling every aspect with the expertise that comes from years of experience.

Your commercial property deserves a roof built to last. When you’re ready to invest in the durability of a built-up roof, hiring a professional ensures it’s done right.

When it comes to protecting your investment, experience makes all the difference.