Why Understanding the Roof Installation Process Matters

The installation process for a home’s roof involves critical phases that determine the longevity and performance of your investment. Here’s what you need to know:

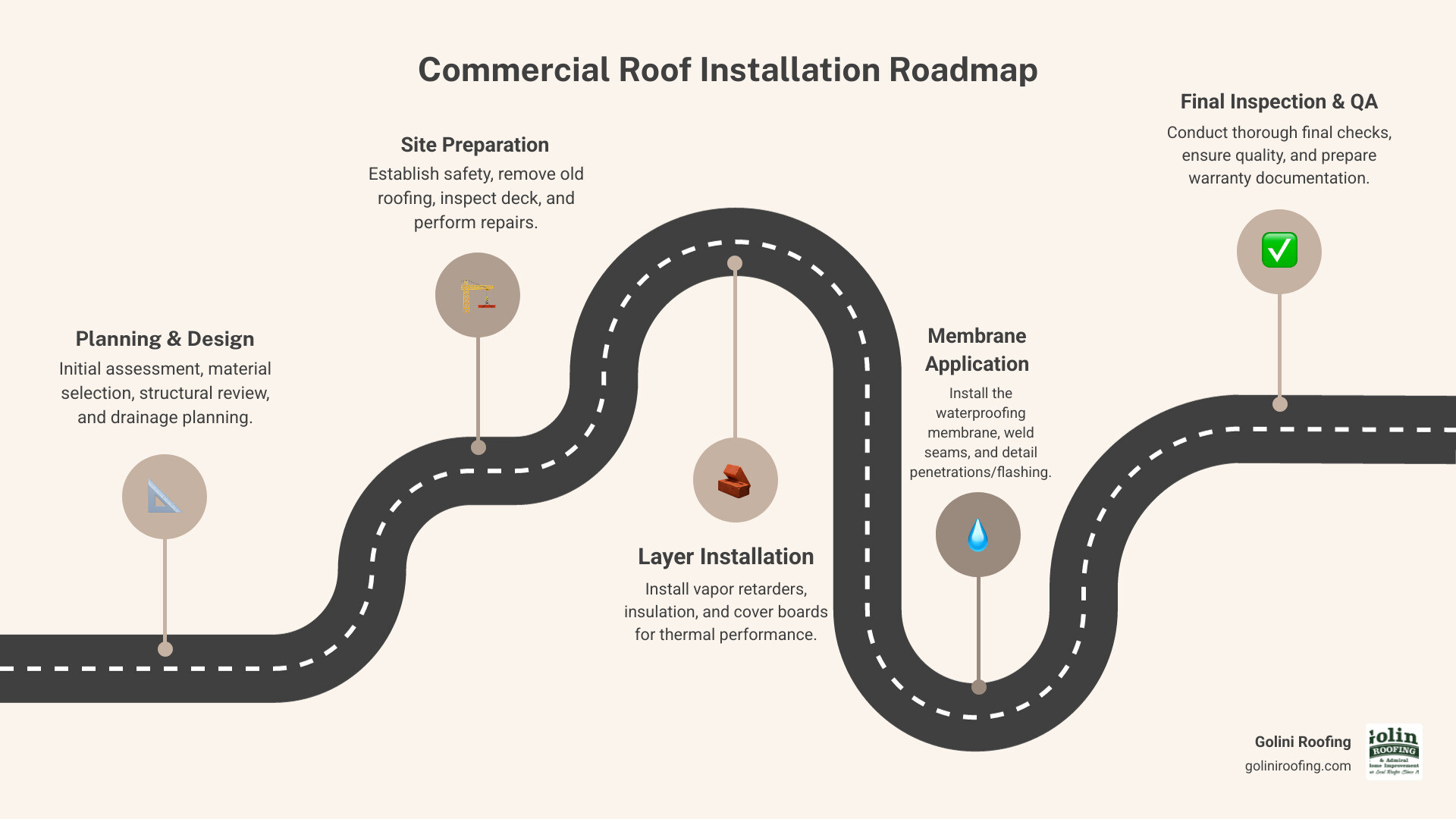

- Planning Phase – Initial assessment, material selection, and structural evaluation

- Preparation – Removal of existing roofing, deck inspection, and surface cleaning

- Installation – Underlayment placement, insulation (where applicable), and shingle or tile attachment

- Sealing – Flashing installation, ridge vent detailing, and waterproofing around penetrations

- Quality Control – Final inspection, testing, and warranty documentation

- Maintenance Setup – Establishing inspection schedules and maintenance protocols

A new roof for your home is a major investment. A quality installation protects your family, maintains energy efficiency, and prevents costly interior damage. A poor job can lead to leaks, structural damage, and premature failure, costing thousands to fix.

The stakes are high because residential roofing systems are complex, often featuring multiple roof planes, valleys, chimneys, and skylights that require specialized materials, proper attic ventilation, and expert installation techniques. Every shingle course, flashing detail, and layer must work together as an integrated system.

I’m Jack Golini, and I’ve been overseeing the installation process for residential roofing projects since 1982. With over 35 years of hands-on experience, I’ve guided homeowners through every phase of their roof installation, ensuring quality craftsmanship and long-lasting results.

This guide walks you through each phase of a professional roof installation, from planning to maintenance. You’ll learn what happens at every step, what materials work best, and how to ensure your investment delivers decades of reliable protection.

Basic roof installation vocab:

- how to install asphalt shingles

- installation process for architectural shingles

- shingle installation process

Phase 1: Planning and Designing Your Roof System

Before any physical work begins, the most crucial phase of the roof installation process is thorough planning and design. This stage lays the groundwork for a successful, long-lasting system that meets your home’s specific needs and local regulations in Massachusetts.

Our initial assessment starts with a detailed inspection of your existing roof. We look for signs that indicate a replacement is due, such as widespread leaks, shingle granule loss, curling or cracked shingles, or an outdated system causing high energy bills. Sometimes, the roof’s age alone—especially if it’s beyond its specified lifespan—warrants a full replacement.

The home type, whether it’s a cape in Woburn, a colonial in Lynnfield, or a ranch in Wilmington, influences the roofing system design. Each home has unique structural and ventilation needs. We evaluate your roof’s structural integrity to ensure it can support the new materials, especially for heavier systems like tile or multi-layer asphalt shingles.

Proper drainage is paramount for any pitched roof. Poor drainage can lead to ice dams, shingle damage, and leaks. We design systems that effectively channel water into the gutters and away from the foundation, incorporating proper roof slope, drip edge, and strategically sized and placed gutters and downspouts. This ensures your roof and gutter system perform optimally through all seasons.

For more information about how we tailor our solutions to your specific needs, please visit our page on More info about our roofing services.

Choosing the Right Materials and Methods

Selecting the right material is a cornerstone of the roof installation process. The market offers many robust options. For residential roofs, architectural asphalt shingles are a popular choice, known for their balance of cost, durability, and curb appeal. Other options include wood shakes or slate, each with its own performance characteristics and aesthetic.

While older 3-tab shingle systems are less common in new installations, they historically offered a cost-effective solution. Premium shingle systems are celebrated for their enhanced durability and longevity, often lasting 30 years or more when installed correctly.

Beyond the material, the attachment method is equally critical:

- Nail patterns and fastening: Properly placed and sized roofing nails secure shingles to the deck and provide excellent wind uplift resistance.

- Underlayment selection: Synthetic or felt underlayments add an extra layer of protection against water infiltration.

- Ice and water shield: Self-adhered membranes in vulnerable areas like eaves and valleys guard against ice dams and wind-driven rain.

Our team will recommend the best approach based on your home’s structure, local wind and snow codes, and budget.

Understanding Roofing Warranties

A critical aspect of the roof installation process is understanding the warranty. These typically come in two forms: manufacturer and contractor (or workmanship) warranties.

- Manufacturer warranties cover defects in the roofing materials, ranging from 10 to 30 years or more. They often cover material replacement but may not include labor costs.

- Contractor warranties, provided by us, cover the quality of the installation workmanship. This is where our 35 years of experience truly shines.

It’s vital to review what is covered (materials, labor, leak repair) and what is excluded (damage from natural disasters, unauthorized repairs, lack of maintenance). Many manufacturer warranties are only valid if the system is installed by a certified contractor. Choosing a reputable and certified roofing contractor ensures your warranty remains intact. For a deeper dive into warranties, the NRCA guide on warranties and why they are important offers valuable insights.

Phase 2: Deconstructing the Layers of a Residential Roof

To appreciate the roof installation process, it helps to understand the components of a typical residential roof. It’s an engineered system of layers, each with a specific function to protect your home.

- Roof Deck: The structural foundation (typically plywood or OSB sheathing) that supports the entire roofing system and any rooftop loads.

- Underlayment: Installed above the deck, this layer provides secondary water protection and helps prevent moisture infiltration.

- Ice and Water Shield: This self-adhering membrane is applied in vulnerable areas like eaves and valleys to prevent ice dam damage and water infiltration.

- Insulation: Proper attic insulation is key to your home’s energy performance, minimizing heat transfer to lower energy bills. We focus on optimal R-values to ensure homes in Wakefield, Reading, or Burlington remain energy-efficient.

- Ventilation System: Ridge vents, soffit vents, and proper airflow prevent moisture buildup and regulate attic temperature.

- Shingles or Tiles: The outermost layer and primary barrier against the elements. This could be asphalt shingles, wood shakes, or slate tiles, installed to create a watertight seal.

The Step-by-Step Roof Installation Process

Once planning is complete and materials are selected, the physical roof installation process begins. Safety is not just a buzzword for us; it’s an unwavering commitment. We ensure every step is performed with the highest safety standards to protect our crew, your property, and everyone on the job site.

Critical Safety Measures During Installation

Safety is always our top priority. We implement stringent safety protocols that adhere to OSHA guidelines, including:

- Fall Protection: Crew members use personal fall arrest systems (harnesses, lanyards, anchor points) and safety nets where needed.

- Personal Protective Equipment (PPE): Hard hats, safety glasses, gloves, and proper footwear are mandatory.

- Perimeter Protection: We install sturdy guardrails around the roof perimeter and open edges to prevent falls.

- Hazard Mitigation: We identify and mitigate potential hazards like electrical lines and skylights before work begins.

- Equipment Maintenance: All tools and equipment are regularly inspected and maintained.

- Worker Training: Our team receives continuous safety training on safe work practices and emergency procedures.

Our meticulous approach to safety ensures the roof installation process is efficient and accident-free.

Preparing the Roof Surface for Installation

A flawless finish begins with impeccable preparation. This stage is crucial for the long-term performance of your new roof.

- Removal of Existing Roofing: We carefully strip away the old shingles and underlayment down to the structural roof deck.

- Roof Deck Inspection: We conduct a thorough inspection of the exposed deck for water damage, rot, or structural deficiencies.

- Structural Repairs: If issues are found, we perform necessary repairs or replace damaged sheathing to ensure the deck is sound and can support the new system.

- Cleaning and Debris Removal: The roof deck must be clean. We remove all debris, dust, and loose particles that could hinder proper adhesion of underlayments.

- Ensuring a Dry, Smooth Substrate: The surface must be completely dry and smooth. Moisture can cause blistering, while an uneven surface can lead to premature shingle wear.

A Closer Look at the Installation Process

With the surface prepared, we begin the precise application of the new roofing system.

- Underlayment Installation: Synthetic or felt underlayment is rolled out over the deck to provide a secondary moisture barrier.

- Ice and Water Shield: Self-adhered waterproof membranes are installed along eaves, valleys, and other vulnerable areas prone to ice dams or heavy water flow.

- Shingle Installation: Asphalt shingles or other residential roofing materials are installed in courses, following manufacturer guidelines for nailing patterns, overlaps, and exposure.

- Ridge Vent and Hip/Ridge Caps: Ventilation components and matching ridge cap shingles are installed to allow proper attic airflow and complete the roof system.

- Detailing Transitions and Penetrations: This is where craftsmanship shines. We carefully detail vulnerable areas like chimneys, skylights, and plumbing vents with specialized flashing to create watertight seals.

- Flashing Installation: Step flashing, counterflashing, and drip edge are installed with precision, often using multiple layers and sealants to create a robust, leak-proof barrier. This attention to detail sets a professional roof installation apart.

Comparing Installation Techniques for Common Roofing Materials

The roof installation process varies significantly depending on the material chosen. Each system has unique characteristics, a different lifespan, and specific installation methods. Here is a comparison of common materials for residential applications:

| Material Type | Primary Installation Method | Lifespan (Years) | Key Features |

|---|---|---|---|

| Architectural Asphalt Shingles | Nailed over underlayment and roof deck in overlapping courses. | 20-30+ | Cost-effective, widely available, good curb appeal, many color options. |

| 3-Tab Asphalt Shingles | Nailed over underlayment and roof deck in uniform courses. | 15-25+ | Lightweight, economical, traditional appearance. |

| Wood Shakes/Shingles | Nailed to roof deck or battens with required spacing. | 25-40+ | Natural look, good insulation value, requires regular maintenance. |

| Slate (Natural or Synthetic) | Mechanically fastened with nails or hooks to solid deck. | 50-75+ | Very long-lasting, premium appearance, heavier material. |

Asphalt Shingle Roof Installation

Asphalt shingles are a popular choice for their cost-effectiveness and performance. The installation process for these materials focuses on proper layering and fastening.

Shingle bundles are opened and installed starting from the eaves, working upward. Starter strips are first installed to seal the lower edge. Shingles are then nailed according to manufacturer specifications, ensuring correct nail placement and quantity for wind resistance. Valleys, hips, and ridges receive special treatment with additional underlayment and cap shingles.

Wood and Slate Roof Installation

These traditional systems offer a distinctive appearance and long service life when installed and maintained properly.

Wood shakes or shingles are installed in overlapping courses with specified gaps for expansion and drainage. Underlayments and ventilation are critical to prevent moisture buildup.

Slate roofing is installed one piece at a time, with each slate fastened to the deck. Layout, overlap, and fastening patterns are carefully planned to achieve a watertight and visually consistent surface.

Both systems require experienced installers because improper fastening or detailing can significantly reduce the expected lifespan.

Post-Installation: Quality Control and Long-Term Maintenance

The roof installation process isn’t complete until a rigorous quality control check is performed. This final inspection ensures every detail meets our high standards and the manufacturer’s specifications.

Our quality assurance checklist includes:

- A visual inspection of all seams for a proper seal.

- Verification of flashing details around all penetrations and edges.

- Checking for proper adhesion or fastening across the entire roof.

- Ensuring all debris is removed and the site is clean.

- Confirming the drainage system is clear and functioning correctly.

Choosing certified applicators like Golini Roofing minimizes risks, ensuring your warranty is valid and your roof performs as expected. We also educate clients on avoiding common mistakes like neglecting inspections or delaying repairs.

Developing a Long-Term Maintenance Strategy

A new roof is a significant investment that requires ongoing care to maximize its lifespan. A proactive maintenance strategy is crucial to protect its value.

Proactive maintenance extends the roof’s lifespan, prevents minor issues from becoming costly repairs, maintains energy efficiency, and keeps your warranty valid.

We recommend professional inspections at least twice a year (spring and fall) to check for:

- Accumulated debris blocking drains.

- Clogged drainage systems causing ponding water.

- Minor membrane damage from foot traffic or weather.

Your roof should also be inspected after severe weather events. Prompt attention to any damage can save you from extensive roof repairs down the line. Our team can assist with inspections and maintenance to keep your roof in top condition.

Frequently Asked Questions about Roof Installation

Investing in a new roof for your home can bring up many questions. Here are some common inquiries about the roof installation process.

How can I determine the expected lifespan of a roof system?

The expected lifespan is influenced by several key factors:

- Material Type: As shown in our table, lifespans vary greatly. Slate systems can last 50-75+ years, while asphalt shingles typically offer 15-30 years.

- Installation Quality: A professional installation by an experienced roofing contractor will always outlast a poor one. Attention to detail is critical.

- Climate Factors: Harsh UV radiation, extreme temperature fluctuations in Massachusetts, snow loads, and strong winds all impact longevity.

- Maintenance Level: Regular inspections and proactive maintenance can significantly extend a roof’s life.

- Manufacturer Specifications: Refer to the manufacturer’s stated lifespan and warranty for a performance baseline.

What are the consequences of using the wrong roofing materials?

Choosing the wrong materials can lead to costly consequences:

- Premature Failure: Unsuitable materials will degrade quickly, requiring early replacement.

- Increased Maintenance Costs: A mismatched material may suffer from frequent leaks and damage, leading to expensive repairs.

- Poor Energy Efficiency: Improper material selection can lead to higher heating and cooling costs.

- Voided Warranties: Using materials improperly can void your warranty.

- Structural Damage: An unsuitable material could be too heavy or fail to shed water properly, leading to structural deterioration.

How often should a home’s roof and gutters be inspected for maintenance?

We strongly recommend a professional inspection at least twice a year, in the spring and fall.

- Spring Inspection: Identifies any damage from winter weather before summer begins, and ensures gutters and downspouts are clear.

- Fall Inspection: Prepares your roof and gutters for winter by clearing leaves and debris and sealing minor issues.

Additionally, have your roof and gutters inspected after any severe weather event. Professional inspections are vital because trained eyes can spot subtle issues an untrained person might miss, catching problems early and saving you money.

Conclusion: Partnering for a Successful Installation

The installation process for a home’s roof is a complex undertaking that demands expertise, precision, and a commitment to quality. From initial planning and material selection to the meticulous installation and final checks, every step is vital to your investment’s longevity and performance.

We’ve explored how careful design, robust safety protocols, and precise application techniques for materials like asphalt shingles, wood, and slate contribute to a successful outcome. We’ve also emphasized the importance of understanding warranties and implementing a proactive roof and gutter maintenance strategy.

With over 35 years of experience serving homeowners in Burlington, Lynnfield, North Reading, Reading, Stoneham, Wakefield, Wilmington, Winchester, and Woburn, we pride ourselves on our meticulous craftsmanship. We understand the unique challenges of residential roofing systems and bring proven expertise to every project.

Choosing the right partner for your roof installation is about securing peace of mind and protecting your home. For a flawless installation that stands the test of time, learn more about our process.